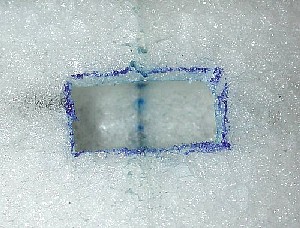

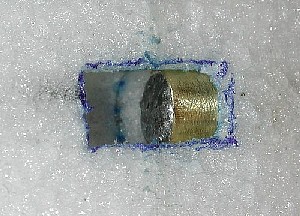

One of the ballast slugs. 5/8" brass

tube filled with melted lead. |

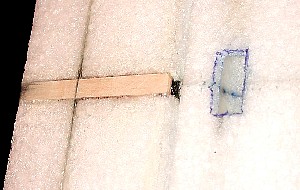

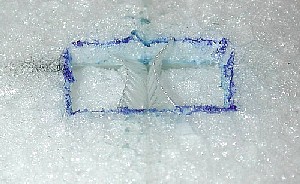

An opening is carefully cut out

through the foam down into the

ballast tube. Don't lose the cover.

Marked around the edges so I'd

see it through the covering. |

A slug half showing.

It disappears all the way down

to the end of the tube. Make

sure the ballast slides easily in

the tube now, because if it's snug

now, it'll be very tight when you're done.

Room for about three 1 inch slugs. |

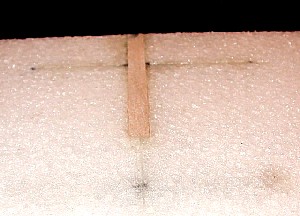

The balsa block is sanded down

and we're looking down into

the ballast hole. |

Sanded down on the bottom too |

The ballast area is now filled with

foam plugs we cut out earlier

to support the cover.

Tape is to make it easier to get out.

Put the little hatch back in place,

and leave it there until the wing is covered. |

![Dscn8779.jpg]()

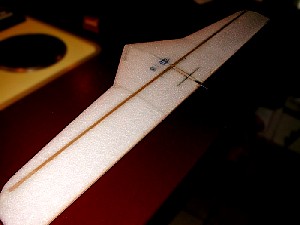

Mask the sides of the spar groove to

protect the wing from glue. |

I expoxied the main spar into the

aluminum joiner with slow epoxy, and

then gooped the whole spar and balsa

strip on top of it. Here it is weighted.

(I actually goofed and used the wrong

wood for the fillers.. Don't do that.

Be sure to use 1/4 x 1/4 x 22" balsa

above spar) |

This is what it'd look like after

you've plained/sanded the balsa

fillers down flush with the airfoil.

(I messed up and used my basswood

strips here by mistake and had to fill

the groove up in places with more Goop) |

I actually installed the basswood

drag spars by the last photo.

Here I put some lithium grease on

the supplied rod and then built up 5

minute epoxy around it between

the basswood spars. Then pulled

the rod out. |

Everything in place.

Spar glued in, filler on top,

basswood drag spars installed

and everything sanded down. |

The opening for the tail boom. |